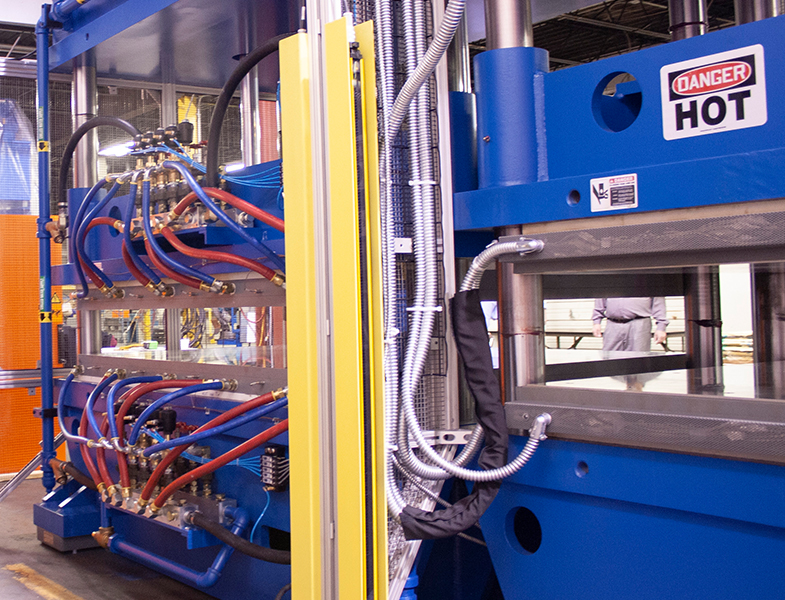

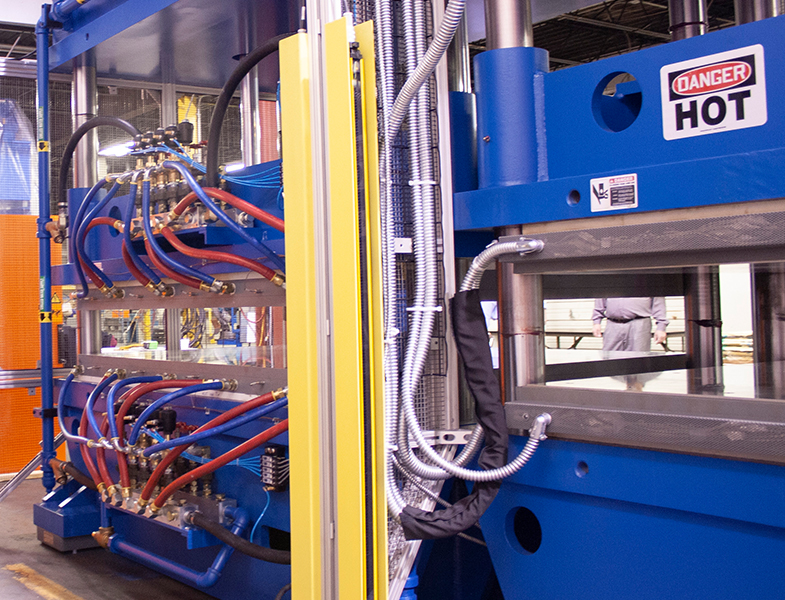

Temperature Controlled

Neff can add hot and cold platens to all of our frame styles and use them in a variety of applications including molding, laminating, binding, and composites. We have designed and manufactured presses using electric, steam, and oil with temperatures ranging from 100°F – 1200°F. Neff offers a variety of control hardware and platforms for your application.