Trimming

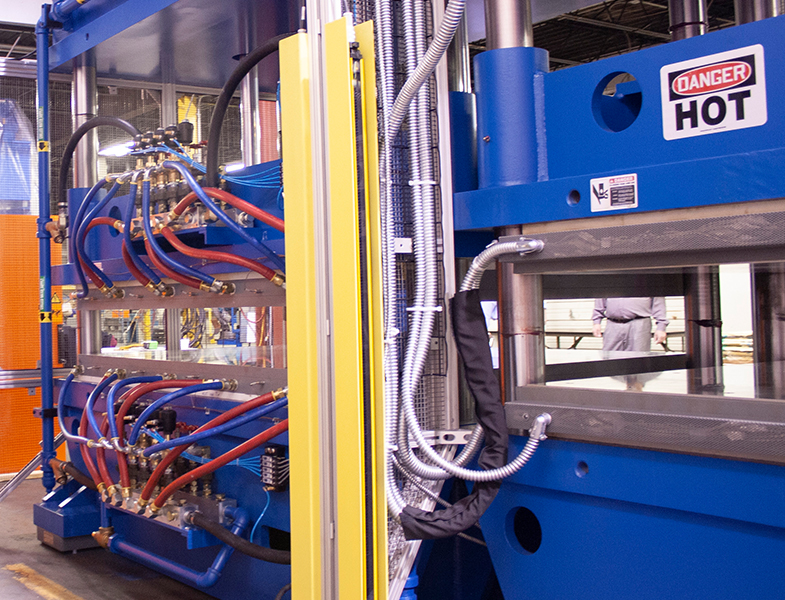

Neff Press designs presses for trimming applications in a variety of frame styles. Trimming operations produce a part where controlled geometry and the initial casting, forging, molding and forming, need excess material removed. We have designed systems using Neff’s pad shift, tooling, robot integration, vison, and scrap conveyance. Trim presses offer you an economical option for finishing operations.