NEFF PRESS BRIQUETTING 101

INCREASED SCRAP MATERIAL VALUEThe MetalBrik System helps recover or reduce your material costs in a number of ways; increased scrap value, reclamation of valuable cutting fluids, reduced labor costs, elimination of EPA issues, and increased floor space.

WHY METALBRIK?

TURN SCRAP INTO CASHMETALBRIK ADVANTAGES

- Remove/Reuse metalworking fluid for recycling

- Reduce Chip-specific labor costs

- Increase scrap value

- Eliminate Hazardous Waste Handling Issues

- Reduce Metal Volume up to 20:1

- Reduced Transportation costs

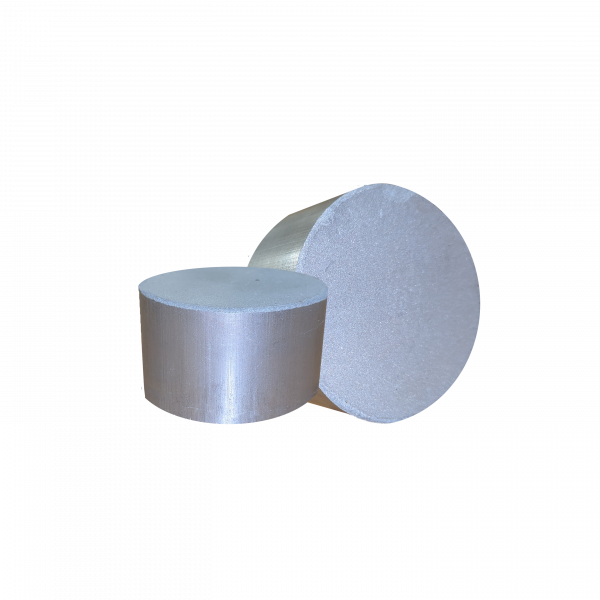

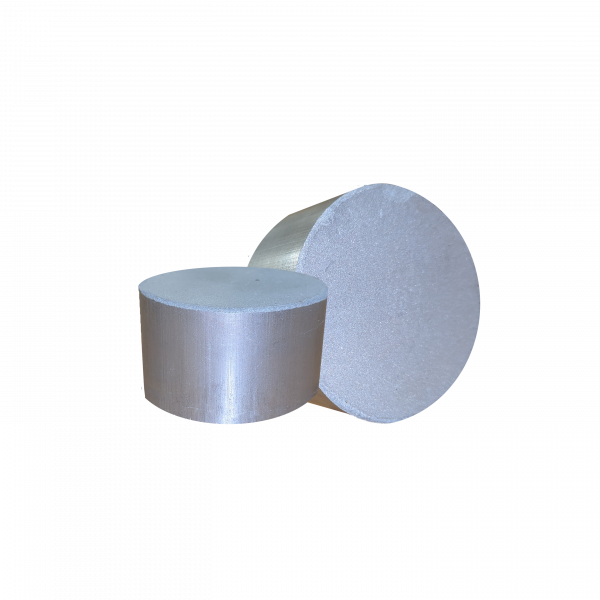

Aluminum

Magnesium/Zironium

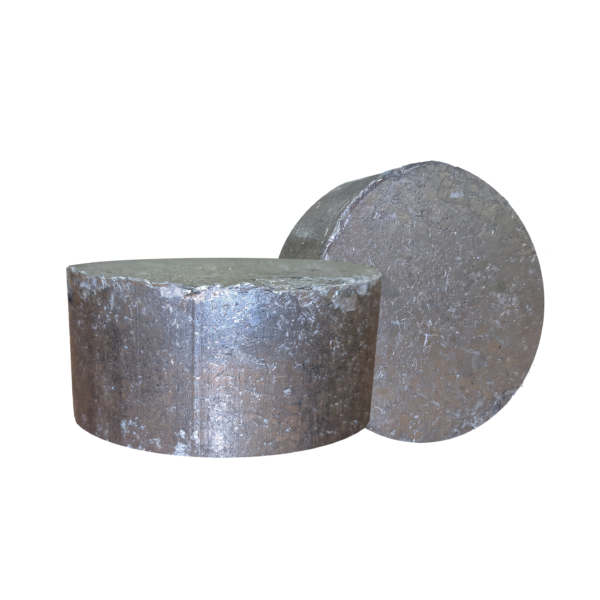

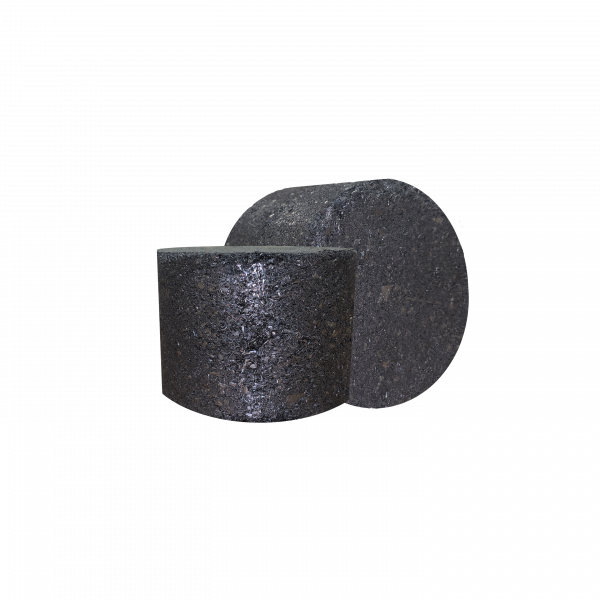

Grinding Swarf

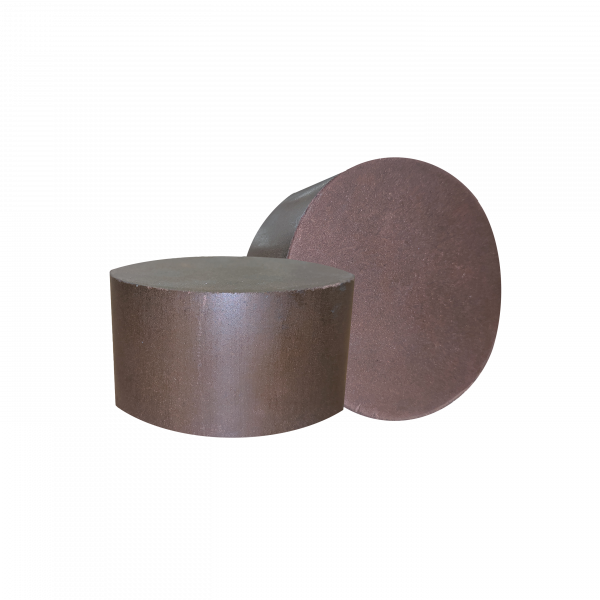

Copper & Brass

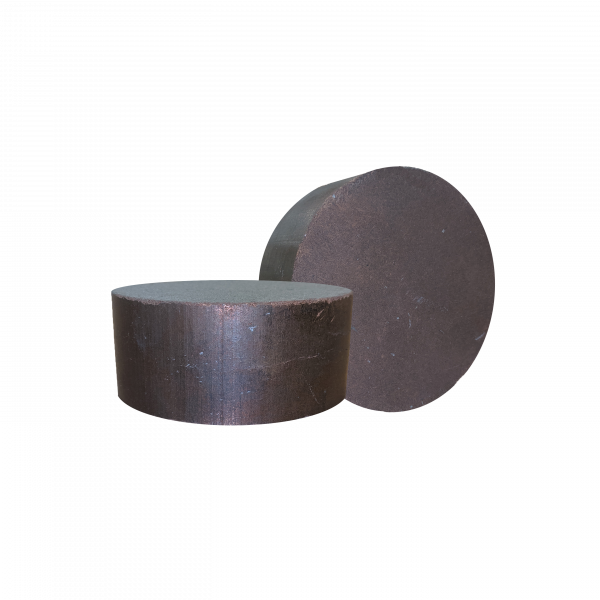

Steel & Stainless Steel

Cast & Ductile Iron

Nickel & High-Temp Alloys

Titanium

EPA Compliance

Keeping our Planet and Production CleanMetalBrik eliminates handling requirements under EPA hazardous waste and used oil regulations. Compressed Briks are up to 99.5% fluid-free, and thousands of gallons normally lost on metal chips can be recycled.

View Briquetters