Automotive Industry Project

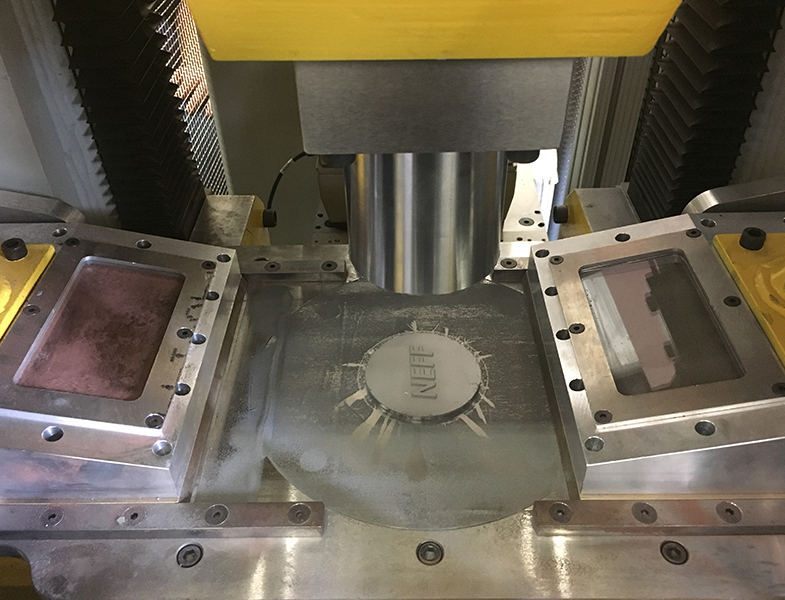

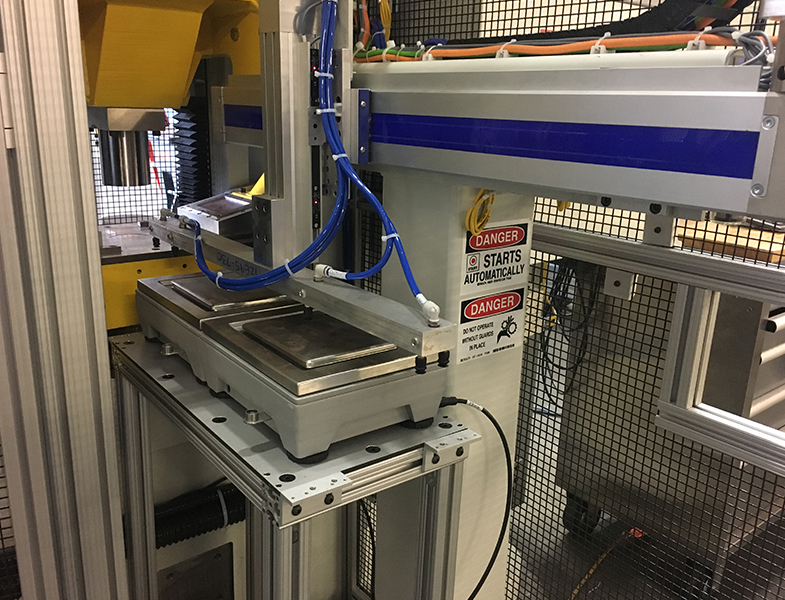

Rail-Guided 200 Ton Powder Compacting Press.Neff Press designed and built 6 rail guided 200 ton powder compacting presses and 3 rail guided 125 ton coining presses for the automotive industry. The dual compaction press uses a servo driven powder feed delivery system, capable of running two unique powders and producing a part every eight seconds.

This press uses a scale to ensure all parts are the correct weight. If the part doesn’t fall within specification, the system auto corrects. This style frame was chosen for its precise guidance and robust design. Neff was responsible for integrating a pick & place unit, a scale, and servo actuators.