Careers

Neff Press is always looking for qualified individuals.

As an Industry leader in manufacturing custom hydraulic presses, we are a Equal Opportunity Employer with a drug-free workplace. We offer competitive compensation, including incentives and benefits, for eligible employees.

Our practice is to retain resumes and applications for open positions from qualified applicants for one year. We use discretion in accepting and retaining unsolicited applications and resumes. We are a Midwest employer that has a strong commitment to positive, progressive employee relations.

Hydraulic Press Tech

As a Hydraulic Press Technician, you will be responsible for building a wide range of presses and integrating numerous types of tooling and high-tech automation systems.

You’ll assemble a variety of hydraulic and pneumatic components. Building and integrating various components/assemblies will be part of daily routine. You will integrate numerous types of electronic components, safety devices, and control systems.

Service Tech

As a Technician, you will be responsible servicing equipment. Neff will train each person on hydraulics, mechanical, and electric systems. This position entails travel, installations, PM programs and interfacing with our customers maintenance and engineering teams.

Additional duties include:

-

Rigging large components on and off trucks (forklifts and overhead cranes)

-

Documentation of service calls

-

Traveling from 25% to 50%

Control Panel Tech

As a Neff Press control panel technician, you will use your knowledge and hands-on experience to build high-quality logic and motor control panels and be responsible for the layout and construction of complex industrial control systems. You will work alongside our Engineering department to ensure specifications and safety designs conform to or exceed the scope of the project.

Welder

As a Neff Press welder, you will be working with pre-cut shapes, fabricating and welding water-tight tanks, various types of box-tube and angle-iron frame structures, and cutting/welding steel pipe assemblies. Responsibilities will include the fabrication of frames, along with drilling, taping, bolting parts together, and cutting and threading pipe. We utilizes all the latest welding equipment available.

Machine Painter

As a Neff Press Painter, you’ll be responsible for the painting of industrial equipment, including a variety of steel frames, and many other parts and structures. We utilize all the state-of-the-art equipment for applications of primer and finish paints with pressure-assisted HVLP systems to achieve high-quality finishes.

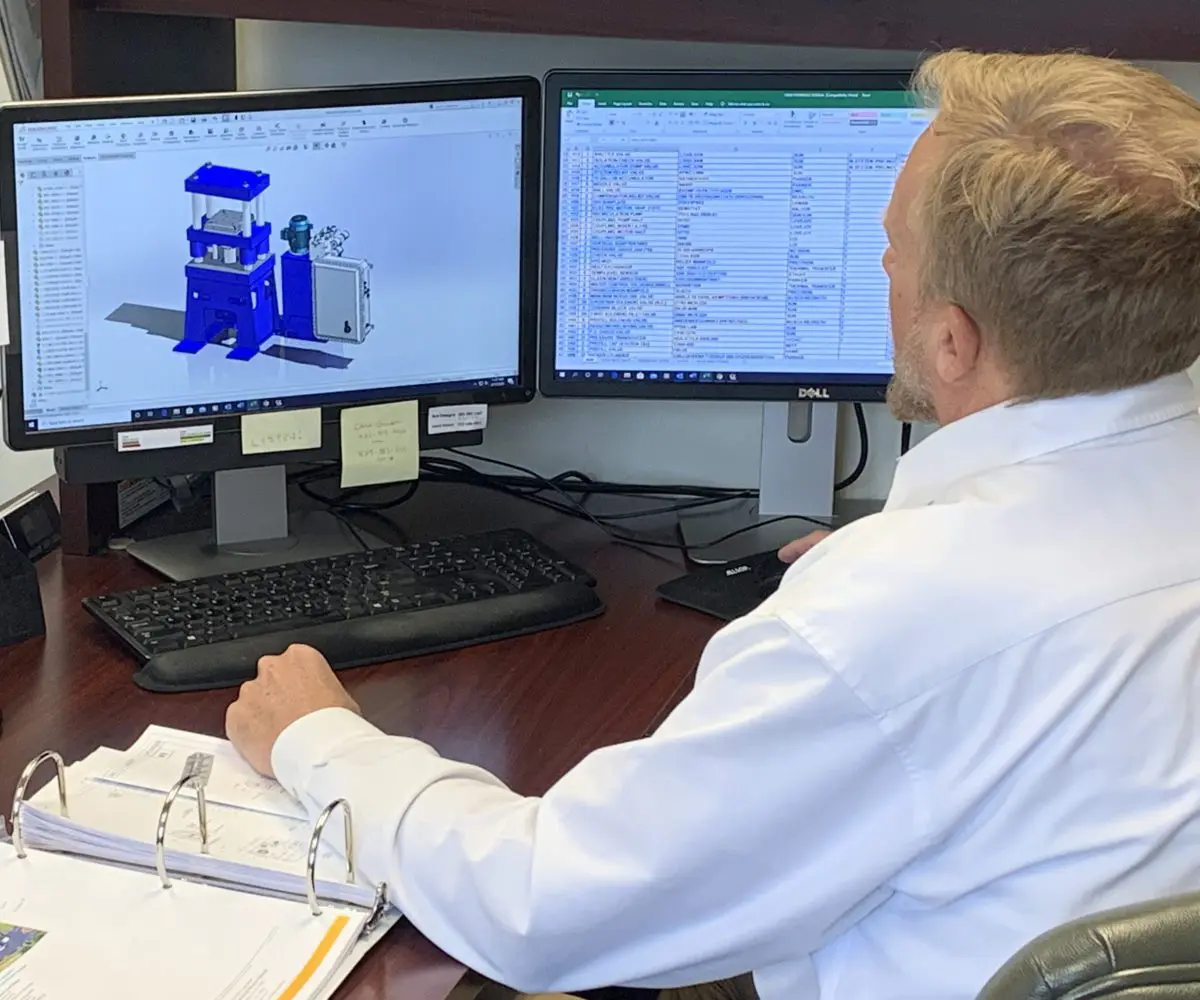

Engineer

As a Neff Press engineer, you will become part of a team that has led the hydraulic press industry for decades. This individual will participate in the design and commissioning of custom hydraulic press projects. Each of our engineers enjoys the benefit of seeing a design through from start to completion – managing all aspects and feeling the pride of accomplishment. You will become familiar with complex hydraulic and control systems and integrate automation with our line of hydraulic presses.